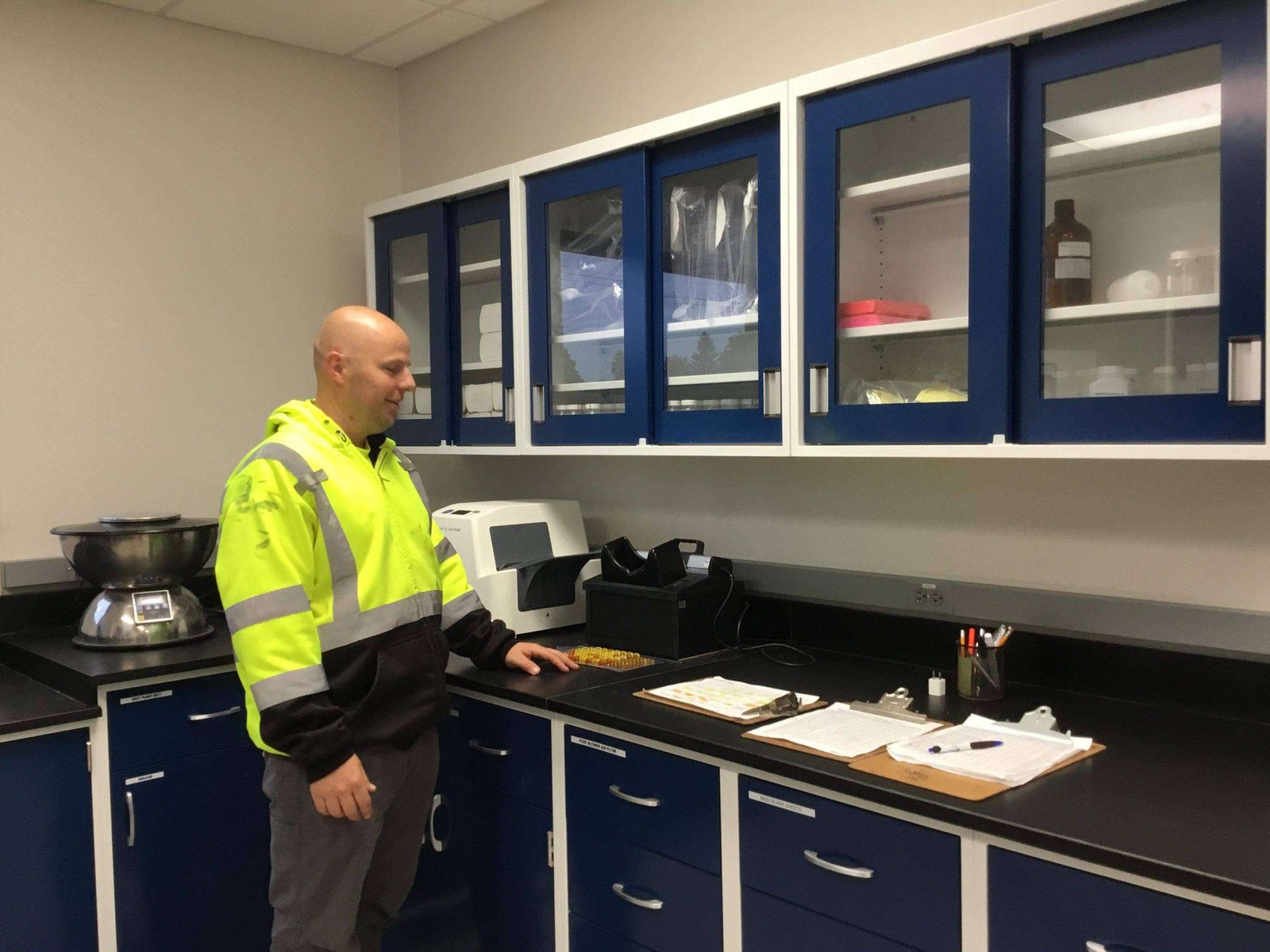

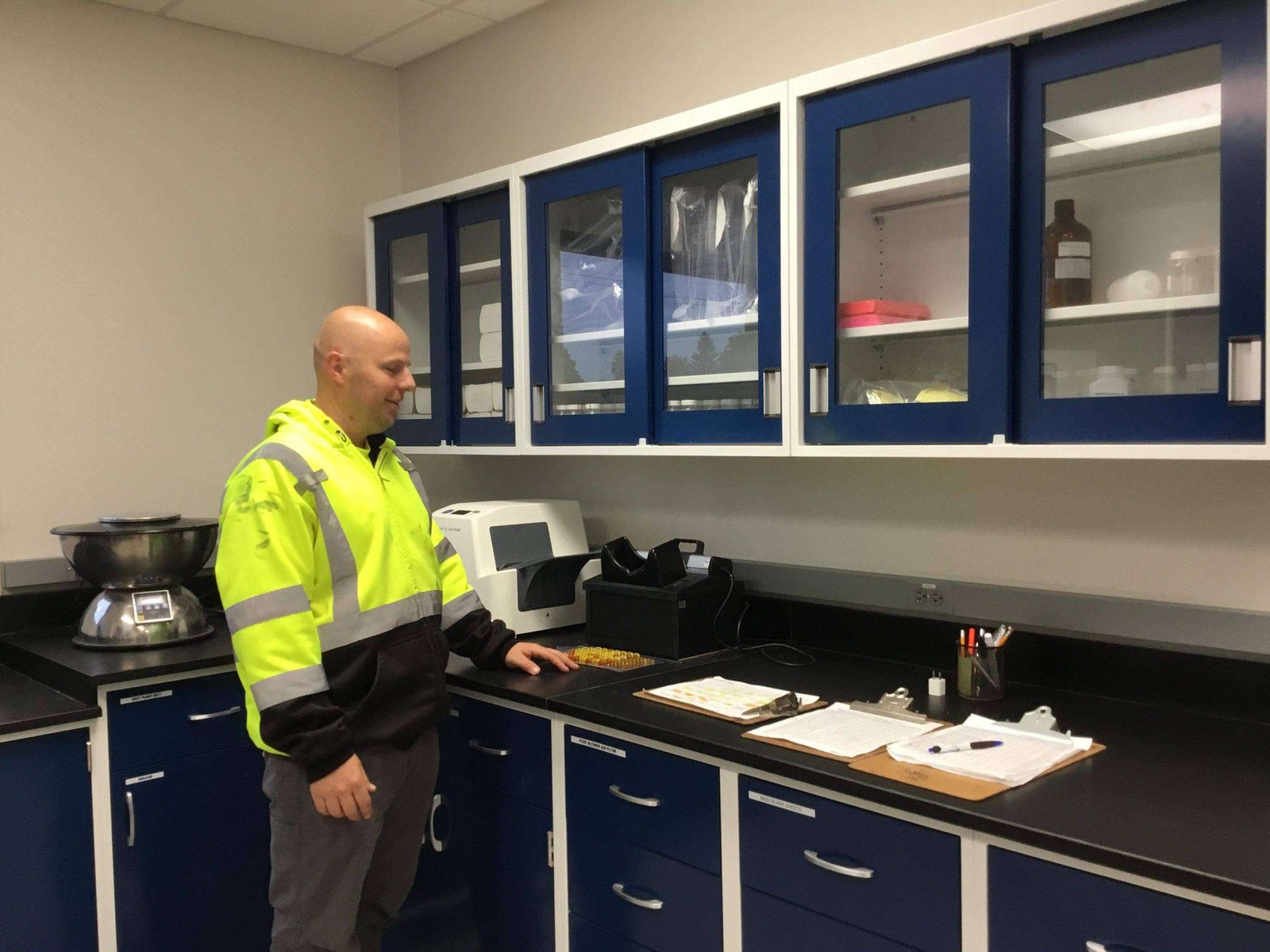

HEADWORKS BUILDING … In the past, after the sewage came through the pump station, it was strained through a bar screen as the first step of treatment began. Mahlman had to rake off all the large items such as paper, feminine products, and any other items that should not have been flushed. “We would gather 4-5 gallons a week of trash and had to do that everyday,” Mahlman explained. The smell in the building was nasty, thus making for a very unpleasant task. The brand new Headworks building was built to replace the old, and is outfitted with a grit and solids removal system that includes a large disposable bag hanging at the end of the pipe. All the items that should not have been flushed are screened out and fall into that bag, which is removed once a week. “That bag can be left up to a month,” Mahlman explained, “but we take it off once a week for sanitary and odor reasons. On the left is Mahlman and village maintenance crew member, Matt Axford. (PHOTOS BY REBECCA MILLER, STAFF)

By: Rebecca Miller

West Unity opened their wastewater treatment plant for tours on October 12, 2019 during the village’s Fall Fest. The plant’s new equipment has been up and running since October 2018, and plant manager Randy Mahlman who’s official title is Water and Wastewater Supervisor for West Unity, has had a year to work out the kinks. “It is a huge improvement in every way over what we had before, even after the 1998 upgrade,” Mahlman said.

The process of getting this new plant took about four or five years, starting with applying for grants and determining what was needed as the EPA has classified West Unity as a Village that needs an EPA Class 2 Plant. One of the greatest things for West Unity is that the village received a grant for 100% forgiveness of a loan principal from the Ohio EPA Water Pollution Control Loan Fund, the total project cost, which was $2.68 million, was completely covered. This allowed them to purchase some extra equipment, making the place’s care even easier, more efficient and cleaner.

In their flyer which was printed for the Open House, the improvements were listed as:

•“addition of variable speed drives to the three existing raw sewage pumps

•New mechanical self cleaning raw wastewater influent screen

•Vortex type grit removal system

•New Headworks building to house the screen and grit removal equipment

•Replacement and upgrade of the two existing oxidation ditch aeration rotors with new rotors including variable speed drives

•Final clarifier equipment repair

•Upgrade of the ultraviolet disinfection system with a new self-cleaning system

•New administration building including lab facilities, office, restroom and a garage bay

•New supervisory control and data acquisition system (SCADA) to monitor various plant parameters.

The revised upgraded treatment facility has an average day design capacity of 325,000 gallons per day with a peak day capacity at 1,460,000 gallons per day.”

OXIDATION DITCHES … After the sewage has been strained there, it goes to a splitter box, which can be seen at the far end of these ditches, with the stair platform on top of it. The Splitter Box divides it and redirects it into the two oxidation ditches. The new aspect about the ditches is that they have much larger and more efficient Aeration Rotors which make the dirty water swirl around, filling it with air and helping to start the separation process. Mahlman and Axford can be seen here standing between the new rotors. The previous rotors didn’t incorporate enough air to keep the ditches from freezing on top in the winter. Each of the long oval ditches hold 116,500 gallons of waste water, continually swirling in opposite directions, making it look like a large figure 8, earning it the nick-name, “the racetrack”. As the water moves in the oxidation ditches, the solids coming through the splitter box are being mixed in with what is already there. The constant inflow of new waste feeds the microscopic bugs and small worms which are breaking the waste down continually.